Summary

- Crews have spent the past 8 months working on or inside the bridge nearly every day to complete Phase I stabilization – a critical milestone that sets the stage for upcoming rehabilitation (Phase II) of the bridge.

- You can see some of these stabilization elements from the ground, like the carbon-fiber wrapping.

- Some elements are inside the bridge. You’re probably most familiar with the post-tensioning strands, and maybe you saw them in our bridge tour.

- You might also remember that we helped the bridge find some major stress relief back in November with the Pier 18 bearing release and replacement.

- Finally, we installed a new intelligent monitoring system to track crack progression and have been performing regular ‘arm’s length’ inspections throughout this stabilization process.

- Even though you might not see it from the outside, we are already working efficiently to plan and complete Phase II of our repairs so the bridge can reopen in 2022.

As many of you know, crews have spent the past 8 months working on or inside the bridge nearly every day to complete Phase I stabilization – a critical milestone that sets the stage for upcoming rehabilitation (Phase II) of the bridge.

Last month, we wrapped up the emergency measures we started in the spring to stabilize the West Seattle High-Rise Bridge and prevent further cracking. As of late December, all work platforms and rigging have been removed from both sides of the bridge.

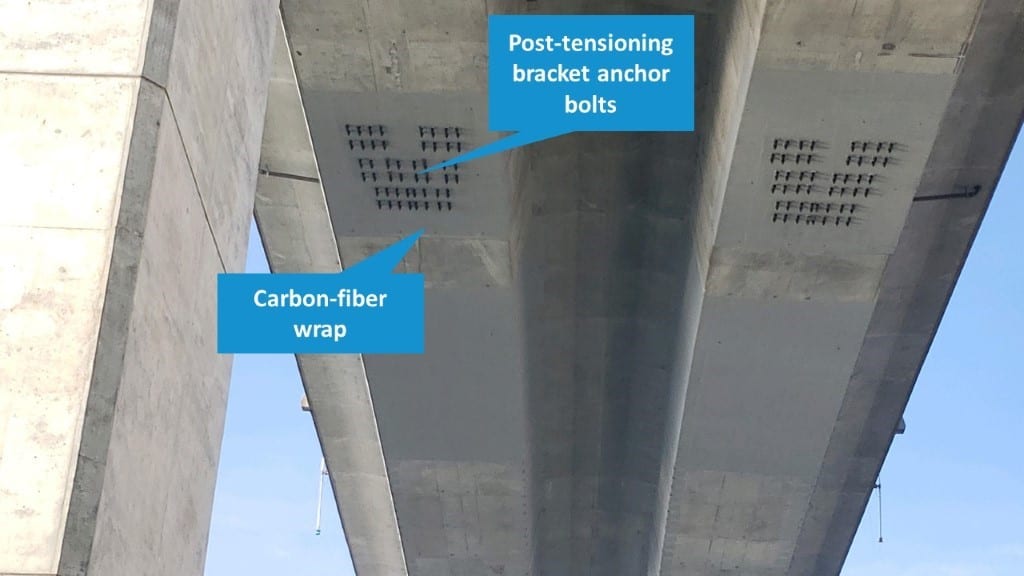

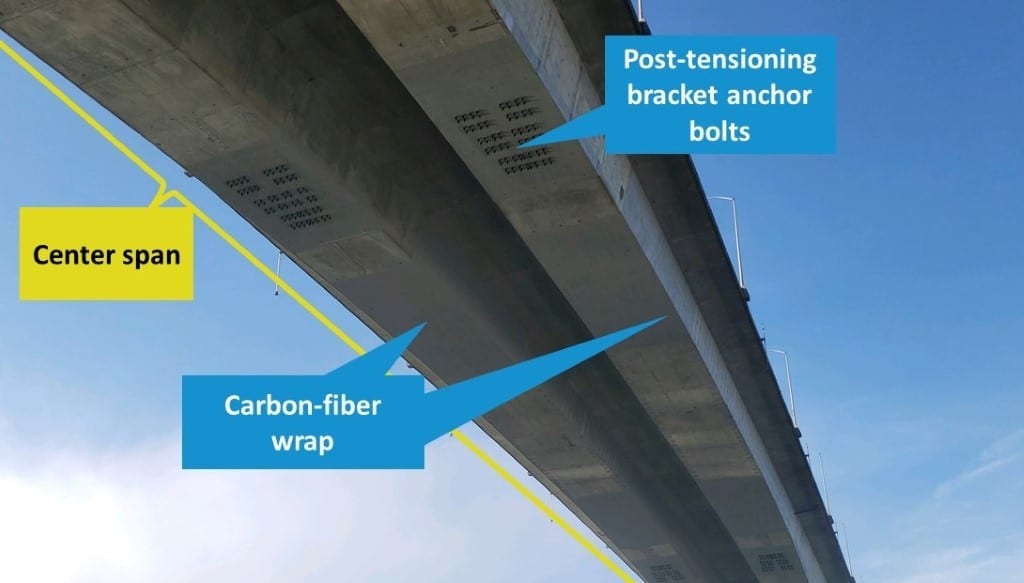

You can see some of these stabilization elements from the ground! Take a look at the carbon-fiber wrapping, for example.

Wrapping sections of the bridge with carbon fiber-reinforced polymer helps support the now-stabilized bridge. We started installing carbon-fiber wrap on the bridge’s center span in August 2020 and completed this work in December 2020.

If you happen to be walking, rolling, scooting, or biking across the Spokane St Swing Bridge (low bridge) and look up, you might be able to see the newly applied wrap. It is affixed to the bridge using a super-strong glue called epoxy.

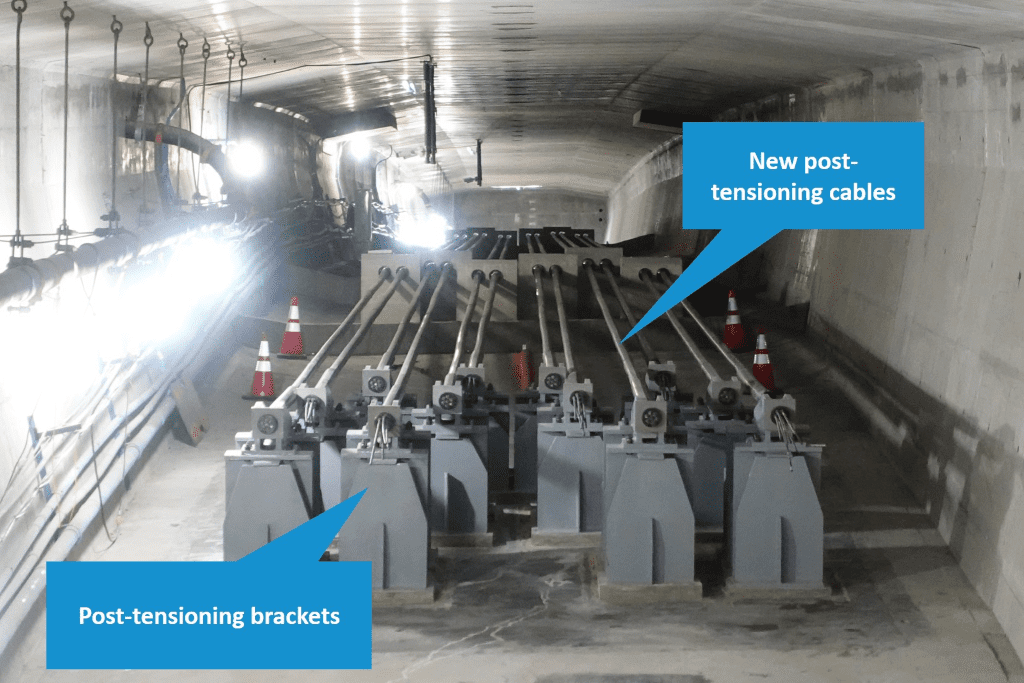

Some elements are inside the bridge. You’re probably most familiar with the post-tensioning strands, and maybe you saw them in our bridge tour!

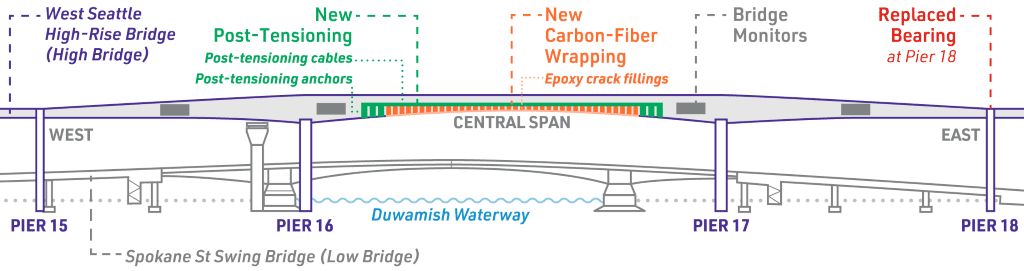

When some bridges are built, engineers build high-strength cables into the bridge’s concrete girders to support the concrete. These post-tensioning cables compress, or tighten, the concrete before vehicles travel on it, allowing the bridge to carry heavier loads.

The high bridge has two kinds of post-tensioning:

- Newly installed cables running along the floor inside the bridge girders, as shown in the image above

- Original cables, which run through hollow pipes that were built into the concrete during bridge construction

Post-tensioning steel cables, or “tendons,” reinforce the bridge structure, which provides resistance to cracking. The bolts, visible on the underside of the bridge (see image above), secure the post-tensioning in place. During the first week of January, we finished the last round of coating for the post-tensioning brackets to protect the new system.

When we post-tensioned the high bridge in 2020, we added more cables inside the bridge girders (not inside the concrete itself) so the bridge can better support itself and respond to environmental factors such as weather, earthquakes, vehicle strikes, or other external forces.

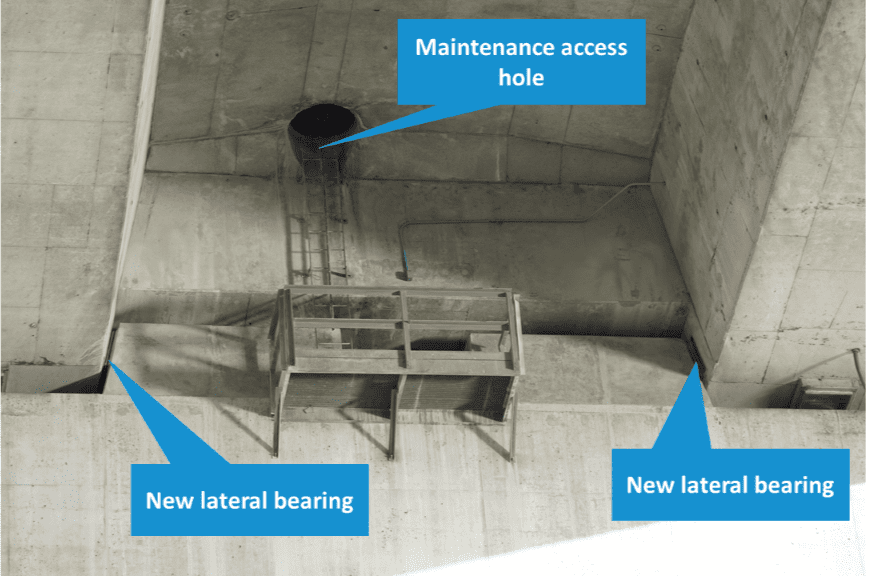

You might remember that we helped the bridge find some major stress relief back in November with the Pier 18 bearing release and replacement.

Expansion joints exist between sections of the bridge to help make it more flexible and create a buffer between different parts of the bridge that may move in different ways. This helps isolate stress points and prevent the bridge from tearing itself apart as different sections push and pull on each other.

Pier 18’s lateral bearings – rectangular pieces of neoprene that act as cushions – were compressed and bulging, indicating that two critical parts of the bridge that are normally independent of each other were rubbing together, creating undesired stress on the bridge.

Together with the contractor, we determined the best way to “release” the bearings so they are no longer compressed and allow the bridge to move as it should. Using a temporary platform and specialized equipment, we precision-demolished the concrete surrounding the bearings. We then installed the new bearings and poured new concrete to hold them in place.

We also installed temporary measures to slow the spread of cracks and a new intelligent monitoring system to track crack progression.

SDOT Project Manager Kit Loo showing the epoxy injections inside the bridge. Photo Credit: Katie Olsen.

Part of the intelligent monitoring system. Photo Credit: Katie Olsen.

In the spring, the contractor installed interim measures to slow the spread of cracks, including epoxy injections and carbon-fiber wrap, at the distressed locations.

In May 2020, we installed a new monitoring system consisting of additional movement sensors, crack monitors, and monitoring cameras throughout the bridge. These monitors are improving our understanding and tracking of the health of the high bridge, with greater precision and with real-time data.

Even though you might not see it from the outside – as is the case of most of the post-tensioning work inside the bridge – we are already working efficiently to plan and complete Phase II of our repairs so the bridge can reopen in 2022.

Our 24/7 monitoring doesn’t stop just because Phase I stabilization work is complete. We’ll continue around-the-clock monitoring and regular visual inspections of the bridge. Full bridge repairs depend upon how the newly stabilized bridge behaves in response to seasonal temperature changes (like cold weather).

Together with our consultant, WSP, we are developing the design for Phase II rehabilitation. Our goal is to bring a contractor on board this spring. Phase II construction is scheduled to start in fall 2021.

While we work to Reconnect West Seattle through other routes and modes of transportation, we are looking forward to having the high bridge back in action in 2022!

Stay up to date on all things West Seattle Bridge:

- Keep an eye on our blog and website for ongoing updates

- Sign up to receive West Seattle High-Rise Bridge project update emails.

- Email us at WestSeattleBridge@seattle.gov with questions.