Summary:

- Status at-a-glance:

- Completed: Installed temporary detour route for people biking around the closure

- Completed: Removed damaged hydraulic turning cylinder for rehabilitation

- Completed: Reprogrammed the eastern bridge span computer control system to temporarily operate the eastern bridge span on one cylinder

- Underway: Replacing valves and hoses on eastern bridge span hydraulic power unit (HPU) to ensure hydraulic fluid does not flow backward and damage bridge

- Ahead: Commission and test the reprogrammed and repaired bridge

- Ahead: Safely reopen the bridge to the traveling public and remove temporary bike detour

- Read more:

Related posts:

- 1/3: Spokane St Swing Bridge update: Flooded power conduit repaired as we prepare to remove a damaged hydraulic cylinder

- 12/29: What we’re doing to maintain and preserve the Spokane St Swing Bridge

- 12/27: Spokane St Swing Bridge remains closed while SDOT repairs machinery damaged after ice storm power outage

- Read all updates about the bridge closure and detour route information

Crews worked hard over the weekend and successfully removed a damaged hydraulic turning cylinder inside the Spokane St Swing Bridge. This represents a significant step forward in the repair effort. It allows us to test temporarily operating the bridge on one turning cylinder, replace hydraulic power unit (HPU) valves and hoses on the eastern span, and move closer to reopening as soon as possible.

We know this closure has affected many travelers in West Seattle and throughout Duwamish Valley communities, and we thank you for your attention to safety while traveling during the closure.

Recap of work to remove damaged hydraulic cylinder

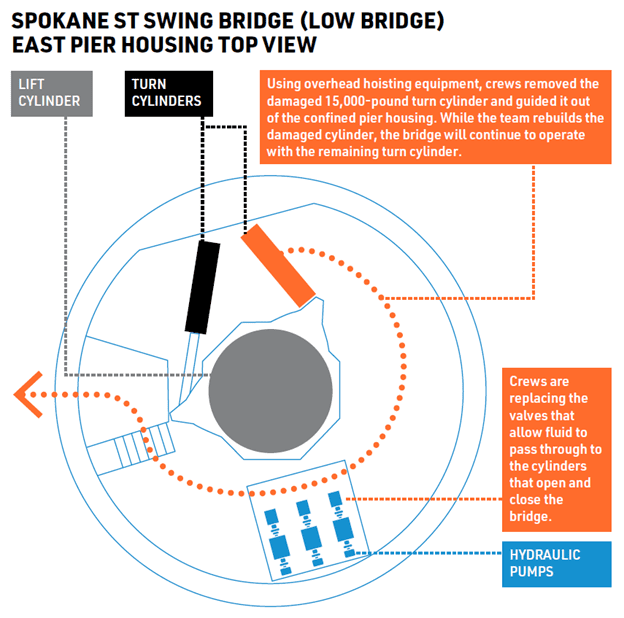

The massive turning cylinder was removed over the weekend and transported to an off-site hydraulic repair facility for overhaul. Removing the cylinder was a 12-hour process that involved hoisting the 15,000-pound cylinder onto an overhead rail system and carefully moving it outside the bridge pier housing. Our crews then used a forklift to move the cylinder onto the back of a truck to transport it to the repair facility.

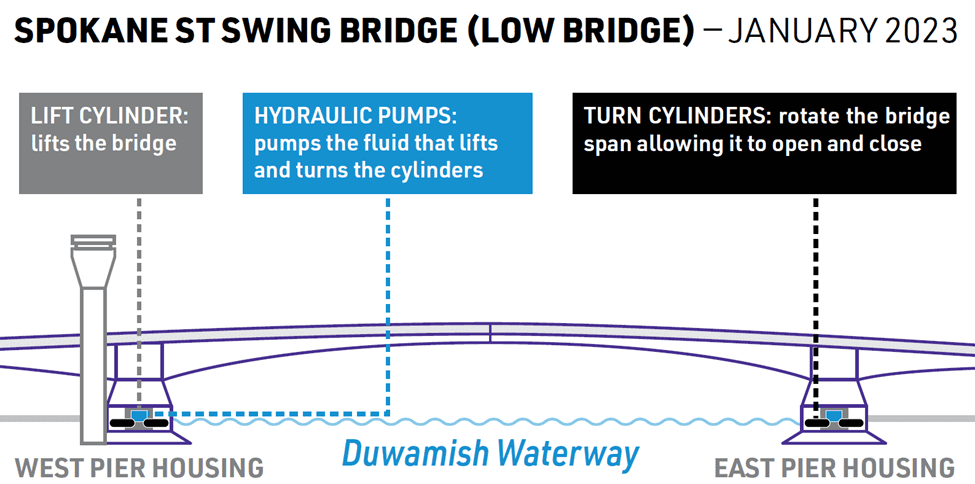

While this cylinder is being refurbished, we’ll operate the eastern span of the bridge on the remaining one turning cylinder (the other two turning cylinders that move the western span of the bridge are still in place). Bridge engineers have reprogrammed the computer system which controls the bridge equipment.

We are now working to reconfigure the hydraulic system to function with one cylinder. We are also replacing the valves and hoses on the hydraulic power unit (HPU) pumps, which send fluid to the cylinders which open and close the bridge. During our testing on Monday, we determined these valves need to be replaced to ensure the bridge operates safely and reliably. We found that 3 of the 4 valves we are replacing were broken.

Once we’ve finished replacing the valves and hoses on the HPU, we’ll continue testing, opening, and closing the bridge so that we can verify it can safely be reopened to the public. While the eastern bridge span runs with one cylinder, opening and closing the bridge for passing ships will take about 10-15 minutes longer than usual.

Upcoming bridge work

Over the coming months, there will be additional bridge closures to reinstall the repaired cylinder and to complete other aspects of the Spokane St Swing Bridge Rehabilitation Program. We already completed work to strengthen the bridge structure in October 2022 and are also planning to replace several other hydraulic components.

This work will be vital to keep the bridge reliably in operation for today and the future.

Preparations to overhaul all four of the bridge’s hydraulic turning cylinders (including the damaged one) began several months as part of this comprehensive repair and maintenance effort. When the unexpected damage to the cylinder occurred, the planning work we had already completed allowed us to quickly jump into developing a response plan and likely allowed us to complete repairs sooner than if we had been starting from scratch.

We’re still developing the work schedule for these activities. We know that there will need to be some temporary, short-term closures of the bridge during key activities in the coming months, and we will continue to share updates as they’re confirmed.

Detours

In response to the emergency bridge closure, we worked to address the closure’s impact on freight movements and people who bike, walk, and roll. This included building temporary protected bike lane segments on West Marginal Way SW and First Ave S, adjusting traffic signals to keep freight moving, and working with Metro to activate the Transit GO Ticket app for free trips on the Water Taxi or bus rides.

When the bridge reopens, these temporary programs will end, and we will begin work to return the detour routes to normal. We have learned a lot by working through the challenges of building these temporary improvements so quickly, and we expect these lessons will help us to be more agile during future bridge closures. Since work on the Spokane St Bridge is not done and more closures will need to occur this year, we will be more prepared to consider these types of detour options when they happen.

Here’s how you can stay informed:

- Email: westseattlebridge@seattle.gov

- Phone: (206) 400-7511

- Sign up for email updates

- Visit our website