West Seattle High-Rise Bridge. Photo Credit: SDOT.

West Seattle High-Rise Bridge. Photo Credit: SDOT. We have reached our internal milestone for intermediate design of the final phase of West Seattle High-Rise Bridge (high bridge) repairs. This is the latest of multiple critical milestones we have reached on-time in our effort to reopen the bridge in mid-2022. This reflects our aggressive schedule to restore travel to the bridge.

The high bridge was closed to protect public safety in March 2020 after city engineers discovered rapidly growing cracks in multiple locations. We immediately set to work on emergency stabilization work, including installing 10 miles of steel cable inside the bridge, repairing a deformed bearing in the Pier 18 support structure, and wrapping the structure in carbon fiber in multiple locations. These emergency measures successfully halted the cracks from growing larger and kept the bridge standing, but additional work is needed to further strengthen the bridge to support the weight and stress of daily traffic.

Since completing those repairs, we’ve conducted extensive monitoring to ensure that the bridge is performing as expected as we’ve moved forward the design to bring the bridge back into service.

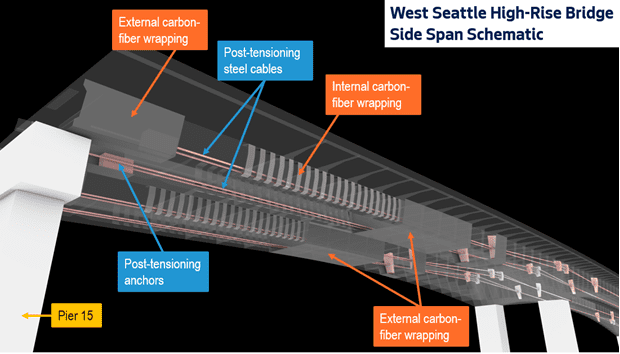

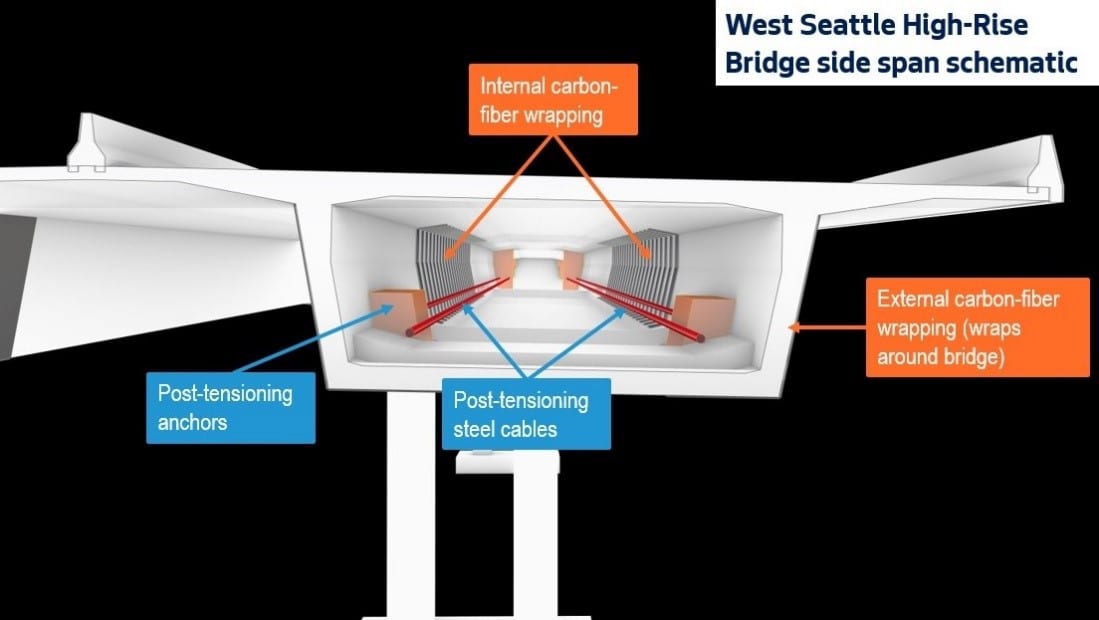

The second and final phase of repairs will build on the same tried-and-true construction methods, including more epoxy injection crack filling, post-tensioning, and carbon-fiber wrapping in the main span. This phase will also include strengthening work on the bridge’s side spans (between bridge columns Pier 15 and Pier 16 and between Pier 17 and Pier 18).

While our teams are confident that these repair methods will be successful in bringing the bridge back into service on schedule, that doesn’t mean the process is simple. It requires careful and complex planning: barging temporary work platforms into place over the working Duwamish Waterway, mobilizing skilled construction crews, and procuring steel cable and carbon-fiber wrap to be installed along multiple spans of the 1,300-foot long and 140-foot tall bridge.

That’s why we’re thrilled that construction contractor Kraemer North America is on board under our pre-construction contract.

Now that we’ve submitted these intermediate design plans, Kraemer’s teams are reviewing them closely and looking for opportunities to maximize efficiency and expedite schedules. This means that Kraemer can now begin contacting suppliers for the custom-made materials necessary to finish repairs. They will also be bringing in local talent to rehabilitate the bridge as we continue to pursue a community workforce agreement.

The intermediate design milestone is right on schedule and sets us up to reach final design in September. At that time, we will finalize construction plans with Kraemer and can share more details about construction methods and schedule.

Here’s what we know now about the details of phase 2 rehabilitation:

Carbon-fiber Wrapping and Epoxy Crack Filling

During phase 1 stabilization, we installed epoxy injections into the concrete and coated that with carbon-fiber wrap to slow the spread of cracks at distressed locations. In phase 2 rehabilitation, we will add more carbon-fiber wrapping on the bridge’s central and side spans. When we add carbon-fiber wrapping to surfaces of the bridge, it’s working in tandem with the steel already inside the bridge to increase bridge strength.

Post-tensioning Steel Cables

Post-tensioning steel cables are installed inside the bridge’s concrete girders (supports) to tighten the concrete before vehicles travel on it, allowing the bridge to carry heavier loads. They also reinforce the bridge structure to prevent it from cracking further. We installed new post-tensioning inside the middle of the center span of the bridge during phase 1, and will add more post-tensioning in the side spans and center span as part of phase 2.

Bridge Monitors

Since phase 1 stabilization, we’ve been using intelligent monitoring techniques to assess how the bridge is responding to our repair measures. As a precursor to phase 2 construction, we will be installing an even more sophisticated, longer-term monitoring system that will allow us to continue to monitor the in-service bridge once it reopens to traffic.

Later this summer, you’ll see teams on the bridge installing the first of the new long-term monitors. These monitors will keep an eye on the bridge’s performance after it opens to traffic in mid-2022 so we can actively manage this crucial connection.

As we move through future milestones, we’ll continue to keep you updated on our progress to reopen the bridge as quickly and safely as possible.

In case you missed it, here’s what you need to know about repair efforts:

- In December 2020, we completed phase 1 stabilization work on the bridge. This work included tried-and-true construction methods designed to halt any further cracking and keep the bridge stable.

- As we developed the preliminary design of the bridge in winter 2021, we conducted extensive monitoring work to ensure that the bridge was performing as expected as weather changed from cooler to warmer weather.

- This monitoring showed that the bridge is behaving as expected, even in February’s snow and July’s heat, keeping us on schedule as we simultaneously worked to complete intermediate design and advertise the construction contract.

- In May, we announced the selection of construction contractor Kraemer North America. Our decision to bring the contractor on board earlier in the design process is just one of the ways that we are expediting the schedule.

- And in June, we confirmed that Kraemer has notice to proceed (NTP) under a preconstruction contract—and that we had received a federal grant of over $11 million to fund the bridge repair effort.